Gas Air Compressor Unloader Valve Adjustment

First turn off the compressor.

Gas air compressor unloader valve adjustment. As tank pressure approaches 135 psi the unloader valve should begin unloading at felt muffler and cause gas engine to slow down to idle speed. The unloader valve should begin unloading at felt muffler and cause engine to idle down. Support seeker patrons and other support. Then remove the stem and the steel ball.

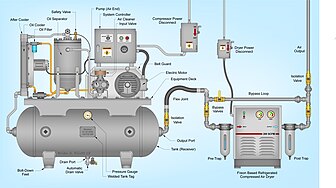

Pilot valve installation and adjusting instructions pilot valve installation 1. Turn the differential screw around clockwise until the pilot seat rests on the internal ball. If it is leaking drain all air from the compressor. Compressor unloader valves are common pieces of equipment on many types of air compressors including reciprocating rotary screw and even gasoline or other fossil fueled air compressors.

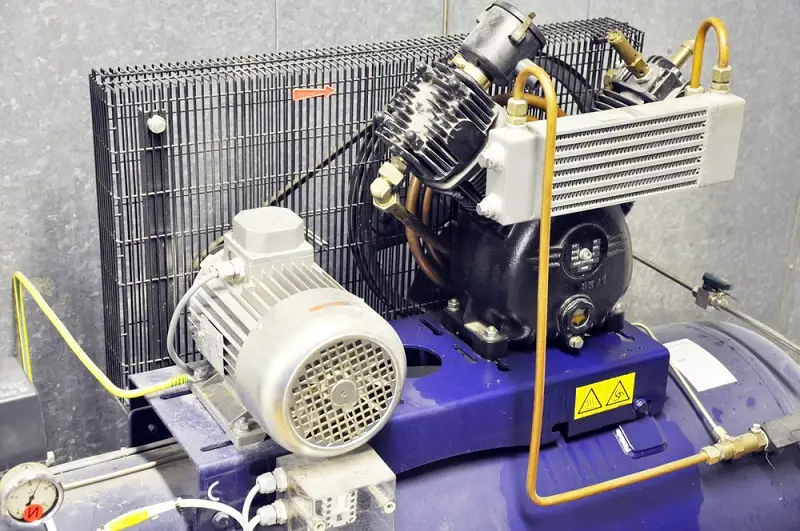

The unloader valve that is shown in the image above is typically found on the side of a compressor pressure switch and is operated by a toggle lever coming out of the side of the pressure switch. Loosen up the differential locknut. Types of compressor unloader valves. This fix my compressor website is focused on the do it yourself and small workshop air compressor and most of these are reciprocating type air compressors.

Loosen differential lock nut d and adjust differential nut c to desired differential. There is no adjustment needed. Place ball into pilot hole in body. Watch this fix before you start buying parts.

Hand tighten pilot cap assembly into pilot hole body then back out turn and differential adjustment. When the compressor is unloading listen and feel for any excessive air being released at the top of the valve or the stem. There are certain steps to follow when adjusting the unloader valve. 1 if pilot valve does not unload as tank pressure approaches 135 psi slowly turn top end setting 4 counterclockwise until pilot starts to unload prematurely at 105 psi.

Http wp me p6ivyu 1wt buy anything on amazon and support se. If it is part of the pressure switch you may have to replace the pressure switch to fix the unloader valve problem. If the unloader valve isn t working replace it. Depending on the make and size of compressor the unloader valve may take many forms.

If pilot valve does not unload as tank pressure approaches 135 psi slowly turn top end setting 4 counterclockwise until pilot starts to unload prematurely at 105 psi. Secure the differential locknut when the differential screw is in contact with the ball.