Glaze Coat Epoxy Repair

Where to use applications.

Glaze coat epoxy repair. Available in 2 0 and 1 0 fl oz carded packaging. Then as another coat fill in the divot. Finally you will apply a very thin coat of epoxy to seal and restore the shine to the countertop. After this make sure to wipe down the surface so it is entirely free of any sanding dust and other debris.

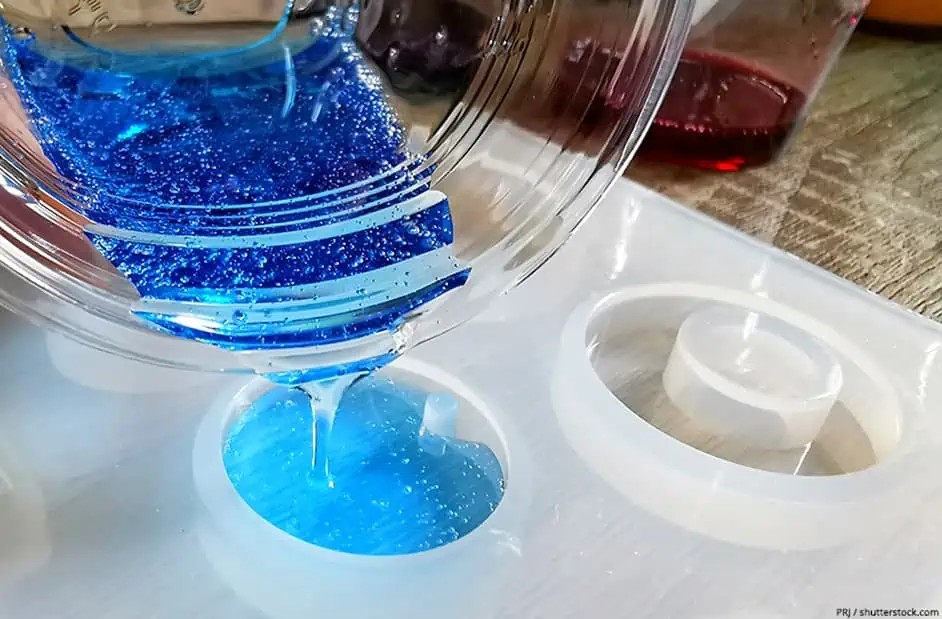

Glaze coat is great for coating tables bar tops preserving pictures and photographs or imbedding items such as coins or rocks. Make sure when wiping you use circular motions. The other downside of using self leveling epoxy inside an rv especially in the southeast in june is the heat humidity and lack of ventilation. Famowood glaze coat is a pour on epoxy coating that can be used on most surfaces.

The ideal temperature conditions to use the epoxy in is 70 f 85 f. The situation got worse once the floor became a lake of epoxy from the flood coat. Famowood glaze coat is an ultra clear high gloss finishing epoxy is ideal for home improvement and craft projects. Clear high gloss pour on epoxy coating one pour equals 60 coats of varnish.

Once cured it can be sanded ground drilled tapped and painted with most paints. Automotive epoxy paste glaze coat high build epoxy coating automotive epoxy paste bonds to metal fiberglass and most plastics and sets in 20 minutes. Famowood glaze coat high build epoxy coating is an ultra clear high gloss finish epoxy versatile enough to be used on just about any surface either smooth or rough stained or painted. The thinned epoxy can better get into the tiny spaces without trapping bubbles.

The contact adhesive and sealant that s the mechanic s choice. Glaze coat famowood wood filler seal all adhesive quickhold adhesive e6000 adhesive e6100 non sag adhesive e6800 uv resistant self leveling glue all purpose adhesive mend vacuum cleaner attachments seal worn or cracked water hoses repair broken ceramic flowerpots marine epoxy paste goop super mend automotive epoxy paste. Seal all adheres with superior strength to all substrates and materials except paper cardboard and styrofoam. It forms a weatherproof bond and offers high impact resistance with no sag.

Seal all is resistant to gasoline oil paint. An uneven hardening of your epoxy resin can lead to dull or even tacky spots. An alternative option would be to use epoxy resin cement. I find it helpful to mix up a small batch of epoxy and dilute it with denatured alcohol and paint on a thin coat making sure to coat the edges and rough areas.

To fix an uneven epoxy finish wait until the epoxy has dried thoroughly and then sand it lightly with fine grained wet sandpaper. This is the space we had to work in.